Measuring Tolerance in Pure Metals: Achieving Precision at One Micron

.png?width=50)

When working with pure metals, achieving and measuring precise tolerances is critical for research and innovation. From scientific experiments to advanced manufacturing, even the smallest deviations can have significant impacts on outcomes.

When measuring the tolerance of a material, Advent Research Materials use state-of-the-art methods to ensure the highest accuracy, including vernier calipers, micrometers and microscales.

What do we mean by the tolerance of a metal?

Tolerance refers to the allowable variation in a metal’s physical dimensions or properties. Whether you’re working with foil, wire, rod, or tube, understanding these small variations is essential for ensuring that materials meet performance requirements.

The tolerances listed below are the typical values Advent would expect for the products we supply.

These should be used as a guide and not absolute values.

Foil: Generally ±10% on nominal thickness.

Wire: Usually better than ±5% on nominal diameter.

Rod: ±10% on nominal diameter.

Tube: ±10% on nominal diameter, wall thickness, and inside diameter.

For specific tolerances on a product line, please contact Advent directly - The team will be happy to assist.

How we measure tolerance for materials below 10 micron: A Step-by-Step Process

For items less than 10 micron in thickness, we are not able to confirm a tolerance of +/-10%, but the tolerance to 1 micron.

Our process for measuring and verifying tolerances in materials below 10 micron combines advanced tools and theoretical calculations, ensuring unmatched accuracy for our customers.

1. Using a Micrometer Calibrated to 1 Micron

The first step in our process involves measuring the physical dimensions of the metal with a high-precision micrometer. This instrument is calibrated to a resolution of 1 micron, allowing us to detect even the smallest variations in thickness or width.

Micrometers are ideal for measuring small and consistent dimensions, particularly for metals in thin sheets, foils, or wires. Regular calibration ensures the accuracy of these readings, making them reliable for critical applications.

2. Cutting and Weighing a Sample

After the initial measurement, we cut a precise piece of the metal for further analysis.

The sample is weighed on a high-precision scale to determine its mass with exceptional accuracy. This weight serves as the foundation for calculating the theoretical thickness.

3. Calculating Theoretical Thickness

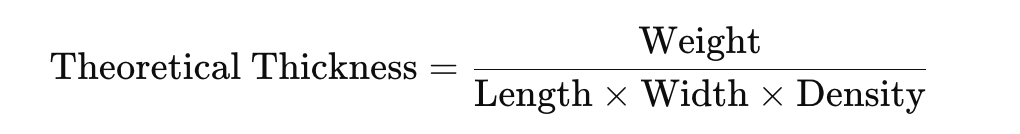

Using the measured weight, dimensions, and the theoretical density of the material (a constant value for pure metals), we calculate the theoretical thickness of the sample.

The formula is straightforward:

This calculated thickness is compared to the micrometer reading to confirm the accuracy of our measurements.

Any discrepancy between the theoretical thickness and the physical measurement highlights potential variations in material consistency or calibration.

Why This Process Is So Accurate

The combination of direct physical measurements and theoretical calculations creates a feedback loop that enhances accuracy. If the micrometer reading and the theoretical thickness agree, we can confidently verify the metal’s dimensions to within 1 micron.

This dual-check system ensures consistency and reliability, even for highly sensitive applications.

Why Tolerance Matters in Research and Industry

Precise tolerances are essential for ensuring the performance and integrity of materials in critical applications including;.

Research Reliability: In scientific experiments, even slight variations in material thickness can affect outcomes, particularly in fields like nanotechnology or optics.

Manufacturing Excellence: For industries like aerospace and electronics, where metals are used in precision components, tight tolerances ensure flawless performance and durability.

Material Optimisation: Measuring tolerance accurately helps researchers explore the properties of pure metals, such as how thickness influences conductivity, strength, or thermal performance.

How We Support Researchers and Innovators

At Advent Research Materials, we understand the importance of precision. That’s why we invest in tools and techniques that deliver the highest level of accuracy possible.

By offering metals with tolerances (usually 10%) measured to within 1 micron, we ensure our materials meet the exacting standards of research and development.

Our comprehensive range includes metals in various forms including sheets, foils, rods, and powders, all ready to be customised to your specific needs. Whether you’re conducting advanced experiments or developing innovative products, our materials provide the precision you require.

Measuring tolerance in pure metals is a meticulous process, but it’s one that pays dividends in research and innovation. By combining micrometer readings with theoretical calculations, we achieve unparalleled accuracy, ensuring our materials perform as expected under the most demanding conditions.

If you’re looking for high-purity metals with precise tolerances, explore our catalogue or contact our team to discuss your requirements.