Tungsten Wire in Action: Supporting Breakthroughs in Medical, Aerospace, and Electronics Industries

.png?width=50)

Among its many forms, tungsten wire is a particularly critical material, indispensable across various high-tech industries.

From medical imaging to aerospace engineering, tungsten wire’s unique properties make it a vital component in applications where performance, reliability, and durability are non-negotiable.

As a supplier to the global scientific community, it’s essential to understand the specific advantages of tungsten wire and how it is applied in cutting-edge technologies.

Properties of Tungsten Wire

Tungsten wire is distinguished by a set of unique properties, well-documented in scientific literature and industry references, making it exceptionally valuable in demanding environments:

High Melting Point: Tungsten boasts the highest melting point of any metal, approximately 3,422°C. This high melting point makes tungsten wire ideal for applications involving extreme heat, such as in light bulbs and high-temperature furnaces.

Electrical Conductivity: Tungsten is not the most conductive metal, but its ability to maintain conductivity under extreme temperatures is crucial for certain applications.This makes tungsten wire suitable for use in electronics and electrical components that operate under high thermal stress.

Tensile Strength: Tungsten wire is known for its exceptional tensile strength, which allows it to withstand significant mechanical stress. This property is vital in applications requiring durability, such as in medical devices and aerospace components.

Low Vapour Pressure: At high temperatures, tungsten exhibits a low vapour pressure, which means it does not easily evaporate. This property is crucial for its use in vacuum environments, such as in electron microscopy and high-temperature furnaces.

Corrosion Resistance: Tungsten wire is resistant to corrosion, particularly in acidic environments. While not as widely discussed as other properties, its corrosion resistance makes it a reliable choice for long-term use in harsh environments.

Thermal Conductivity: Tungsten’s ability to conduct heat efficiently makes it suitable for applications where heat dissipation is critical, such as in electronics and aerospace engineering.

Applications of Tungsten Wire

The unique properties of tungsten wire enable its use across a broad spectrum of industries:

- Lighting: Historically, tungsten wire has been fundamental in incandescent lighting due to its ability to endure high temperatures without melting, ensuring a bright and reliable light source.

- Electronics: In the electronics sector, tungsten wire is used as a key material in microchips, particularly in high-temperature environments. This application is especially critical in automotive and aerospace industries, where temperature stability is paramount, and failure is not an option.

- Medical Devices: Tungsten wire’s strength and biocompatibility make it a key material in medical devices, such as fine needles and electrodes in defibrillators.

- Aerospace and Defence: Tungsten wire is critical in aerospace applications that require materials to perform under extreme conditions, such as in rocket engine components and military ballistics. Tungsten’s exceptional thermal properties ensure reliable temperature measurement during critical mission phases, safeguarding the integrity of aerospace components and the success of missions.

- Thermocouples: Tungsten wire is used in high-temperature thermocouples found in industrial furnaces, jet engines, and gas turbines, where conventional materials cannot withstand the heat.

- Research and Development: Tungsten wire is indispensable in scientific research, particularly in scanning electron microscopy (SEM) and mass spectrometry, where its durability and stability ensure precise results.

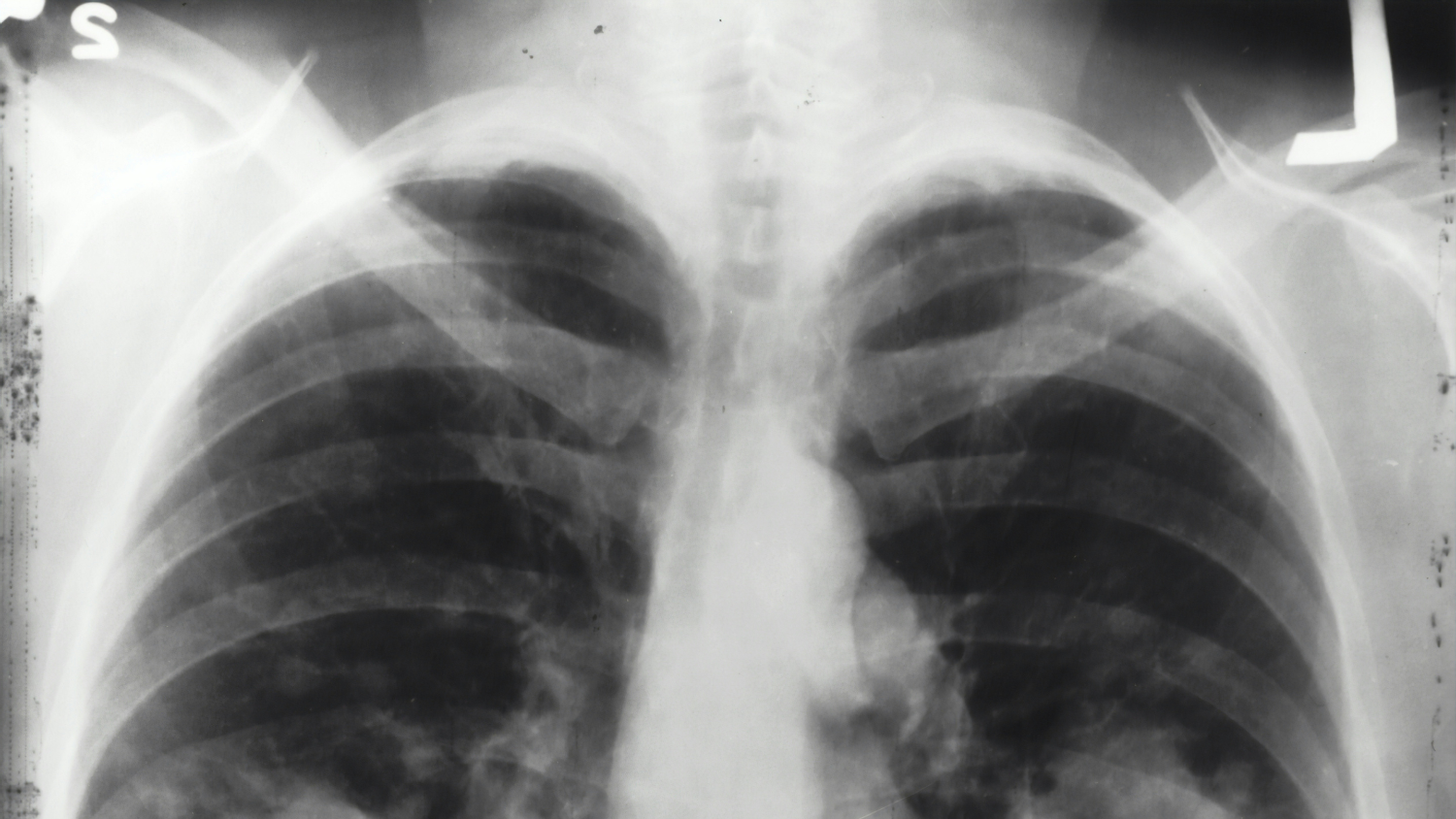

- X Ray Technology - Tungsten wire is a cornerstone material for medical imaging, particularly in X-ray technology. Utilised in the cathodes and anodes of X-ray tubes due to its ability to operate at high temperatures and produce the necessary energy levels for effective imaging, tungsten plays a pivotal role in enhancing the durability and performance of medical imaging devices, leading to improved diagnostics and reduced maintenance costs.

Tungsten wire, with its unmatched properties, is a linchpin in many high-tech applications.

From the precision required in medical imaging to the extreme conditions of aerospace engineering and the intricate demands of electronics, tungsten wire proves its worth time and again.

As a supplier to the global scientific community, understanding the value of tungsten wire is essential.

It’s not just about meeting the demands of today’s technologies but about pushing the boundaries of what’s possible in the future.